The main method to improve the corrosion resistance of seamless pipes

Published:

2022-04-28

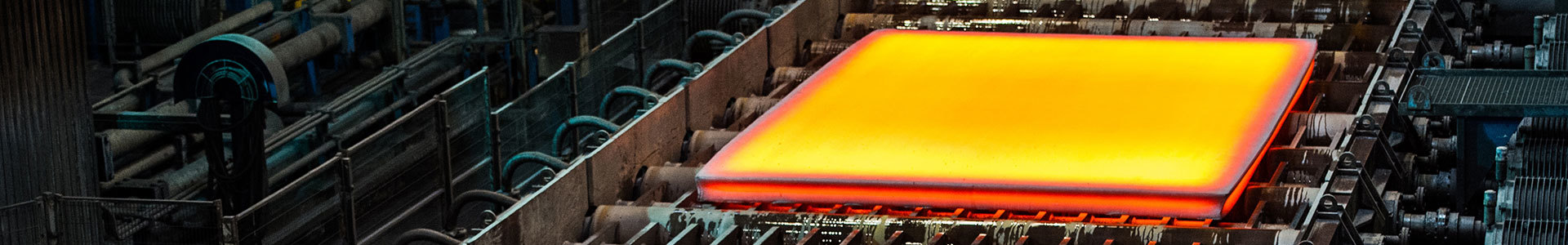

In order to improve the corrosion resistance of seamless pipes, general seamless pipes are galvanized.

In order to improve the corrosion resistance of seamless pipes, general seamless pipes are galvanized.

There are two types of galvanized seamless pipes: hot-dip galvanized and electro-galvanized. The hot-dip galvanized layer is thicker, the cost of electro-galvanizing is low, and the surface is not smooth.

Oxygen blowing welded pipe: used as oxygen blowing pipe for steelmaking, generally small-diameter welded seamless pipes are used, and the specifications are 8/8-2 inches. Made of 08, 10, 15, 20 or 195-Q235 steel strip, some must be effectively aluminized in order to prevent corrosion of galvanized seamless pipes.

Cold galvanizing is electro-galvanizing, the amount of galvanizing is very small, only 10-50g/m2 is recommended, and its corrosion resistance is much worse than that of hot-dip galvanized pipes.

The hot-dip galvanized seamless tube substrate and the molten plating solution undergo complex physical and chemical reactions to form a corrosion-resistant structure of the zinc-iron alloy layer. The alloy layer is combined with the pure zinc layer and the seamless tube base.

Keyword:

Recommended News

What is the use of anti-corrosion steel pipe

2022-09-17

How are seamless steel pipes connected

2022-04-28

TEL: +86-18063568663

WhatsApp : +86-18063568663

E-mail : diana@baixinxinmetal.com

ADD : Yishan Road, Laiwu District, Jinan City, Shandong Province, China